New Digital Design Process

Share

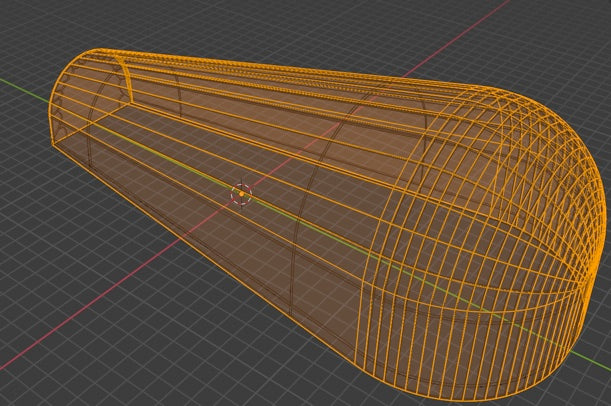

It's the research and development aspect of this business that I really enjoy. And with the world sheltering in place due to COVID-19, I have had plenty of time for that stuff. All that work has paid off, as I am now moving as many pieces as possible into an entirely digital design and production process. Producing molds using 3D modelling techniques instead of physically is a huge improvement for me!

Digital 3D molds will allow me to easily scale the molds I use for my armour. As well, they'll benefit from better symmetry and more consistency. Additionally, I am able to produce digital templates, used to cut my products out of the vacuum formed pieces. All this translates into more varied and higher quality armour in the future. You can see why I'm super excited about this!

The first piece to benefit from this process is my Signature Basket Hilt. Very shortly I'll be replacing the current model with a new design, digitally produced. Following that, I'll be updating my bazubands (allowing me to produce a full complement of sizes there), cops and shoulders. And with those pieces going digital, look for more styles of those pieces coming soon.

Of course, it's not just the act of designing armour on the computer that allows for all these gains. I've had to work out processes to translate those designs into the physical world, such that I'm able to vacuum form my products. I've spent countless hours, and suffered many, many failures along the way. I've learned a ton, and am ready to start sharing the rewards with you folks. The future is bright!